Original article by YUFA Polymer.

�� For inquiry, please contact: info@yufapolymer.com

�� Production Site: Shenzhen, China

When dealing with advanced semiconductor devices, the tray is not a simple accessory—it directly affects yield, reliability and production cost.

For BGA, LGA, CPU and FPGA devices, using a low-temperature tray (125–150°C) often leads to:

· Warpage during baking

· Particle contamination

· Ball deformation or solder shift

· Contact failure (LGA)

· Device scrap and severe RMA loss

And the root cause is simple:

The tray material cannot withstand the required temperature.

Why do these devices require 150–180°C trays?

1. BGA solder balls are extremely sensitive to heat

During baking, test and burn-in, temperatures typically reach 150–170°C.

Any tray deformation will cause uneven stress → solder ball shift → poor reflow quality.

2. LGA pads are sensitive to particles and ion contamination

Low-grade trays tend to release VOCs, ionic residues or particles at high temperatures.

These contaminants can cause LGA contact failure.

3. CPU/FPGA require high-temperature Burn-in

Server processors, AI accelerators and industrial ICs require 160–175°C long-term aging tests.

Only high-temperature resins (PPS/PES/PEI) can remain dimensionally stable under these conditions.

4. High-value IC = extremely high cost of failure

An FPGA can cost dozens or even hundreds of dollars.

A single tray failure can damage an entire batch.

For high-end devices, the JEDEC tray is a critical part of the reliability chain, not a consumable.

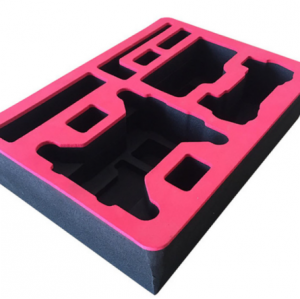

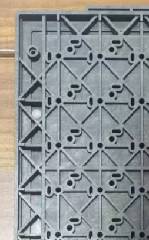

Why choose our 150–180°C JEDEC Tray?

· PPS / PES high-temperature resin

· Excellent dimensional stability under 150–180°C

· Ultra-low warpage for BGA/LGA testing

· Low contamination: no halogen, low ionic, low VOC

· Fully JEDEC-compliant and compatible with global handlers

If you manufacture FPGA, CPU, AI processors, BGA memory, or automotive-grade ICs

a high-temperature JEDEC tray is essential for quality and reliability.

�� Contact Us

YUFA Polymer Products Co., Ltd.

�� Address: Shenzhen, China

�� Email: info@yufapolymer.com

�� Web: www.yufapolymer.com