Warum kundenspezifisch A Antistatische Einsätze sind heute in der intelligenten Fertigung unverzichtbar

✍️

Originalartikel von YUFA Polymer. Für Anfragen oder Weiterverbreitung wenden Sie sich bitte an:

info@yufapolymer.com

.

��

Produktionsstandort: 3. Etage, Gebäude E, North Yongfa Shangliao Park, Bezirk Baoan, Shenzhen, Guangdong, VR China.

⏳ 1. Kontext: Warum die Teileroptimierung wichtiger ist als je zuvor

Im Zeitalter automatisierter Präzisionsfertigung und globaler Logistik reichen herkömmliche Standardverpackungen nicht mehr aus. Die zunehmende Komplexität elektronischer Komponenten – von elektronischen Steuergeräten in der Automobilindustrie bis hin zu optischen Komponenten für die Hochgeschwindigkeitskommunikation – erfordert nicht nur Schutz, sondern auch kontaminationsfreie, ESD-sichere und leicht nachverfolgbare Transportumgebungen.

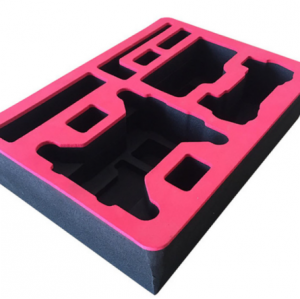

Die Antwort? Eine neue Generation von antistatische Wabenteiler . Sie sind leicht, strukturell stabil und in hohem Maße anpassbar und werden zum Rückgrat moderner Elektronikverpackungen – insbesondere in Anwendungen, bei denen Schäden durch elektrostatische Entladung (ESD) auftreten. Vibrationen oder Verunreinigungen können zu Millionenverlusten führen.

�� 2. Anwendungsfälle in der Industrie: Wer braucht antistatische Wabenteiler?

Antistatische Wabenteiler (auch bekannt als ESD-Messertrennwände) werden heute in mehreren Branchen, in denen hohe Zuverlässigkeit gefragt ist, weithin eingesetzt:

· Automobilelektronik : Für eine sichere innerbetriebliche Logistik von ECU-, TCU- oder Batteriesteuergeräten.

· Halbleiter & Optik : Für die Präzisionshandhabung von optischen Linsen, Wafern und Lasermodulen.

· Unterhaltungselektronik : Für den Transport fertiger Geräte und hochwertiger PCBA-Baugruppen.

· Medizin & Labor : Als kontaminationsfreie Transportbehälter für Diagnosemodule.

· Intelligente Fertigung : Wird als ESD-sicherer Nesteinsatz in Mehrwegbehältern und AGV-kompatiblen Behältern verwendet.

⚙️ 3. Warum spezielle antistatische Trennwände anstelle von generischen Einsätzen verwenden?

Es gibt vier Gründe, warum individuell konfigurierte Wabenteiler herkömmliche Trennwände übertreffen:

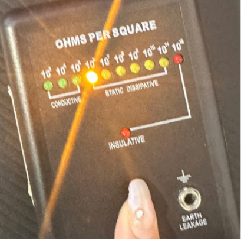

1. Dauerhafte antistatische Leistung (10⁶–10⁹ Ω), unabhängig von Feuchtigkeit oder Abnutzung.

2. Modulares Strukturdesign ermöglicht einlagige, doppellagige (gefaltete) oder EVA-umwickelte Baugruppen.

3. Präzisionsschlitzen ermöglicht eine maßgeschneiderte Anpassung an die Bauteilabmessungen und vermeidet Mikrokollisionen oder Verkantungen.

4. Materialkonformität mit ESD-, ROHS- und Reinraumanforderungen gewährleistet die Kompatibilität zwischen den Einrichtungen.

Darüber hinaus, eigenständige Trenneinsätze bieten die Freiheit, Kartons umzufunktionieren, die Schlitzgeometrie neu zu konfigurieren und die Stückkosten für verschiedene Lagereinheiten zu senken – und bieten den Einkaufsabteilungen so sowohl Flexibilität als auch Lagereffizienz.

�� 4. Technische Spezifikationen und Anpassungsoptionen

Unsere Standard-Wabenplatten verfügen über:

· Dicke : 4 mm

· Basisgewicht : 1200 g/m²

· Oberfläche : Beidseitig antistatisch

· Kern : PP-Wabenzellstruktur (leicht, hohe Druckfestigkeit)

· Konfigurationen :

O �� Einlagiges Schlitzen : Kostengünstig

O �� Doppellagig gefaltet : Höhere Festigkeit für höhere Nutzlasten

O �� Umwickelt mit antistatischem EVA : Verbesserte Oberflächenreibung und Stoßdämpfung

Alle Materialien sind vollständig recycelbar und in Schwarz erhältlich. Optional: PSA-Kleberücken, QR-Code-Etikettierung und Ultraschall-Kantenversiegelung.

�� 5. Wie überzeugt man Stakeholder zum Wechsel?

Käufer zögern möglicherweise, Trennwände als Einzelartikel zu kaufen, aber erfolgreiche Fallstudien zeigen:

· �� Wiederverwendbar : Herausnehmbare Einsätze verlängern die Lebensdauer der Außenkartons

· �� Niedrigere Gesamtkosten : Reduziert Bruch und Nacharbeit aufgrund schlechter Passform in der Verpackung

· �� Bestandskonsolidierung : Eine Kartongröße, mehrere Einlegemöglichkeiten

· �� Schrumpfausschussquote : Speziell für die Klasse 0-Komponentenlogistik

Schulungsteams, um Trennwände als Teil der Schutzverpackungsstrategie – und nicht als Verbrauchsmaterial – hat sich als Schlüssel zur Einkaufsakzeptanz erwiesen.

�� 6. Abschließende Gedanken: Warum es Zeit ist, ESD-Verpackungen zu überdenken

In der heutigen Fertigungslieferkette ist jede Komponente, jeder Handhabungsschritt, jede Verpackungsschicht wichtig. Durch den Einsatz antistatische Wabenteiler Da sie genau auf die Anwendung abgestimmt sind – nicht nur auf die Box –, gewinnen Sie die Kontrolle über das, was bisher Ihr schwächstes Glied war: die Sicherheit der Komponenten während des Transports.

Lassen Sie uns Ihre Verpackung verbessern von ausreichend Zu strategisch .

��

Kontaktieren Sie uns jetzt

So passen Sie Ihr antistatisches Trennwandsystem individuell an:

��

E-Mail:

info@yufapolymer.com

��

Webseite:

www.yufapolymer.com

��

Adresse: 3. Stock, Gebäude E, North Yongfa Shangliao Park, Bezirk Baoan, Shenzhen, Guangdong, VR China.